Línea de producción de guata térmica dura de poliéster de 500 kg/h

Descripción del producto

Detalles del producto

| Lugar de origen: | China |

|---|---|

| Nombre de la marca: | HONGE |

| Certificación: | ISO9001/CE |

| Número de modelo: | HYL-WJM |

Condiciones de pago y envío:

| Cantidad mínima de pedido: | 1 juego |

|---|---|

| Precio: | negociación |

| Detalles del embalaje: | Película de PE o desnuda. |

| Tiempo de entrega: | 150 días. |

| Condiciones de pago: | L/C, T/T |

| Capacidad de oferta: | 1 o 2 líneas cada 120 días. |

500kg/H Polyester Hard Thermal Bonding Wadding Production Line

Description

| Product Name: | Soft And Hard Wadding Thermal Bonding Production Line | Trim Width: | Max. 3600mm |

|---|---|---|---|

| Material: | Polyester Fiber, PP Staple Fiber, Bi-component Fiber, Low Melt Fiber, Wool, Etc. | Specfcation Of Fiber: | 1.5D-15D*51mm-72mm |

| Weight Range: | 60gsm-5000gsm | Production Capacity: | Max. 600kg/h |

| High Light: |

Hard Thermal Wadding Production Line,500kg/H Wadding Production Line,Bonding Wadding Production Line |

||

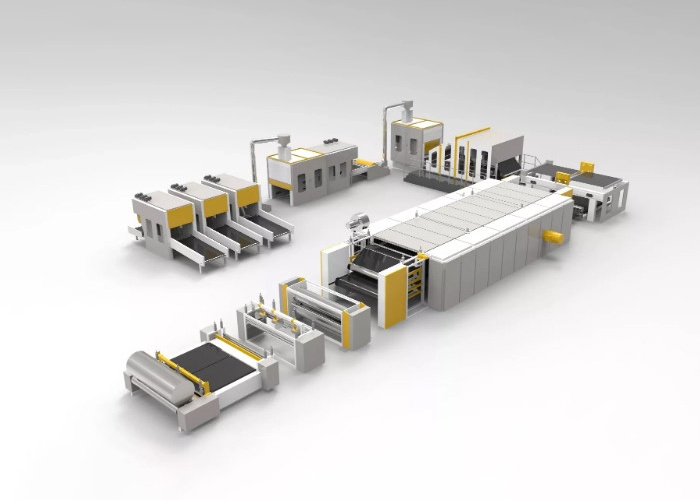

Vertical Cotton and Hard Wadding Thermal Bonding Production Line

Production line description:

Thermally bonded webs are assembled with both synthetic or natural fibers and ensure the creation of light to medium weights at high production speed. It is possible to obtain a homogeneous fiber distribution which results in high-strength nonwovens. The surface weight of the final product ranges from 60 to 5.000 gsm.

The thermobonding line allows the creation of high loft products for the furniture or clothing industry as well as sturdy pads used in automotive and construction industries. Some low melt fiber like PET or PP are mixed as binder.

According to products and tecnical requirments, the production line design is flexible and diversified. The thermal bonding production line bascally consists of fiber openers, hopper feeder, carding machine, cross lapper, thermal bonding oven, winder or cutter and etc.

Technical parameters:

| Working width | 2000mm~3600mm |

|

Weight range |

60gsm-3000gsm |

|

Raw material |

1.5D-15D*38mm-51mm Polyester fiber, PP staple fiber, bi-component fiber, low melt fiber, wool, etc. |

| Process technology | Thermal bonding process |

| Production capacity | max. 300kg/h |

| Applications | quilts, mattress, furniture, garments, insulation materials, etc. |

| Installed power | Depends. |

Products and applications for reference:

Trade information:

| Trade terms | FOB, CNF, or CIF |

| Lead time | 120 days after deposit. |

| Payment terms | 30% advance payment, 70% paid off before delivery. |

| HS code | 8449009000 |

| Warranty | twelve (12) months after mechanical and electrical commissioning. |

| After-sale service | The seller is responsible for installation and debugging. The buyer is responsible for the round-trip airplane tickets, accommodation, medical treatment, safety and relative fees. In addition the buyers should assign translator, workers, electrical cable (from machines to control panel and from power to control panel) and tools for installation to cooperate with the work. Installation cost is USD180/Day/engineer and totally installation period is about 30-40 days depending on well cooperation of the buyer. |

Company introduction:

Until now, we have established 10 series 0f nonwoven machinery all over the country and also expand our business scope abroad, up to date, we have exported production line to Southeast Asia, Europe, South America and Austria, etc.

Contact information:

Email: rainbow@hongyiwf.cn

WhatsApp: +86-15262513303

Productos relacionados

Product

Contacts

Phone: 86-512-52860355

Tel: +86-18962359051 (whatsapp)

Fax: 86-512-52860355

Website: www.hongewf.com

Email: rainbow@hongyiwf.cn

Address: No. 52 Jinxiu avenue, zhitang town, Changshu city, Suzhou city, Jiangsu province, China

Tel:86 18962359051

Phone:86-512-52860355

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:+86 18962359051

Email: rainbow@hongyiwf.cn

We will give you feedback in time